"REVOLUTIONIZING THE GAME BEETWEEN EV and ICE"

AKS ACTIVE Patented technology A transformative Leap for ICE engines in the EV Era

"Revolutionary thermodynamical model for ICE engines, regulating heat transfer within milliseconds cycle"

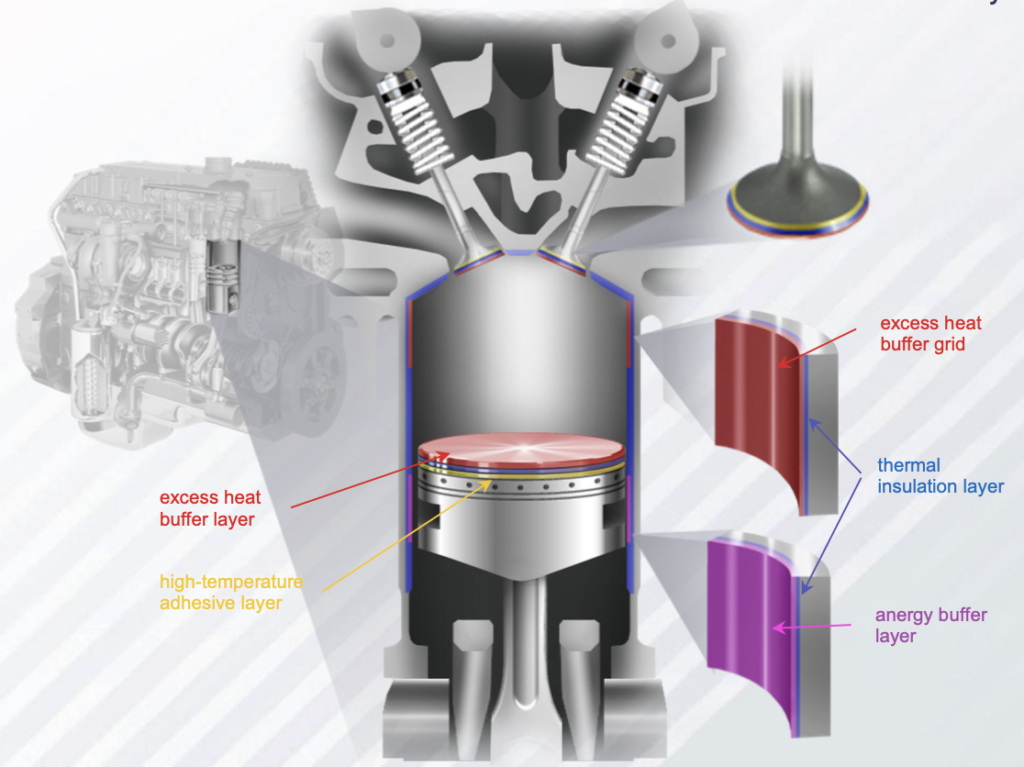

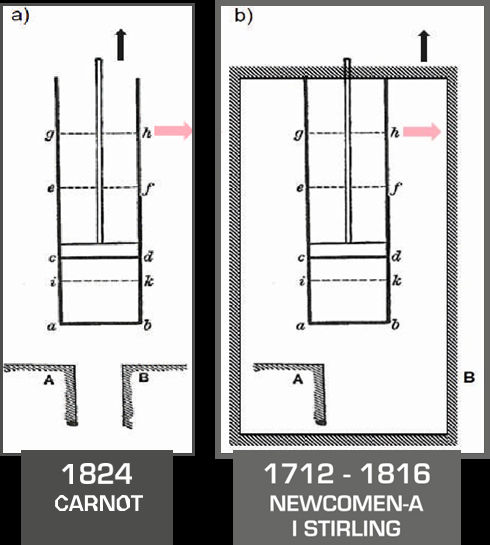

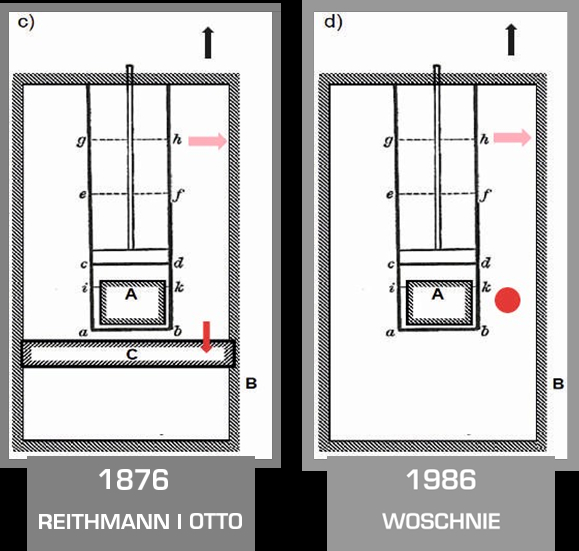

AKS ACTIVE is a revolutionary breakthrough technology capable of reducing fuel consumption by up to 30% backed by patent number DE112017000942.1T 2019. This is achieved through the application of specialized material layers, leading to the thermal activation of the combustion chamber. AKS is an active combustion chamber of a piston engine with an innovative thermal structure, in which excess heat (previously dissipated to the radiator) and portions of exergy (previously expelled with exhaust gases) are internally stored along with the engine's operating cycle. This leads to a revolutionary utilization of fuel, with minimal engine upgrade costs.

WHAT IS AKS ACTIVE ?

The AKS ACTIVE refers to an active combustion chamber of an internal combustion engine with an innovative thermal structure, in which excess heat (previously expelled to the radiator) and portions of energy (previously expelled with exhaust gases) are internally buffered along with the engine's operating cycle. This leads to a revolutionary utilization of fuel, with minimal costs for engine upgrades.

HOW IT WORKS ?

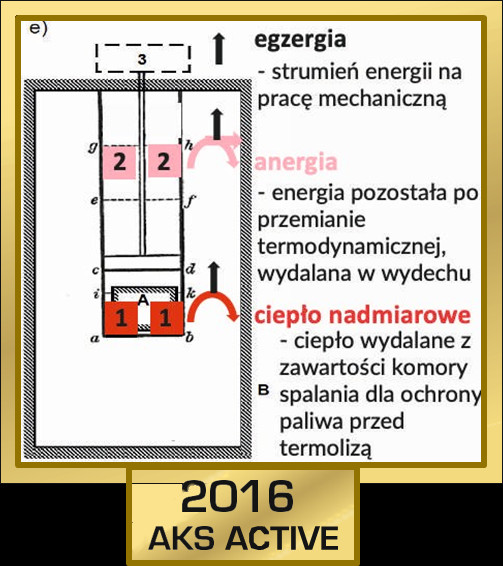

The essence of the technology, as well as its simplicity, lies in adjusting the appropriate surface area and thickness of AKS THERMAL and AKS ISOLATE layers relative to the parameters of a given engine. This allows for directing energy in the combustion chamber precisely where it is needed at a given place and time. As a result, heat is always where it is most needed - a task already handled by the natural processes of thermodynamic processes, which are often misunderstood or incompletely understood.

AKS THERMAL

Example SURFACE: 30 CM2 WIDTH: 0.1 MM

AKS THERMAL is designed to store heat when the chamber heats up, so that it can be released back into the combustion chamber during the next stroke of the engine. Under normal conditions, heat would dissipate to the radiator and be lost!

AKS ISOLATE

Example SURFACE: 30 CM2 WIDTH: 0,1 MM

This layer is designed to retain excess heat generated in the combustion chamber. The principle of operation is similar to that of a thermos. We don't want the heat to escape, so we store it inside, thereby insulating it from the external temperature.

400J HEAT

"THE EXCESS IS ABSORBED BY AKS THERMAL LAYER"

That's as much energy as boiling one glass of water.

"Rudolf Diesel - one of the first creators of the diesel engine - dreamed of an engine without losses due to cooling."

Global success of AKS

Scientific Committee of the 11th ICCHMT Conference (Krakow, May 2018)

Confirmation by world-renowned scientists of the AKS principle, which allows for the overcoming of the Carnot limit. Recognition of the scientific exceptionalism of the AKS project.

Publications in renowned scientific journals.

Journal of Thermal Science Vol. 27, Issue 5, pp. 449-455, DOI: 10.1007/s11630-018-1039-7.4. Physics Journal by AASCIT.

American Journal of Mechanics and Applications

Asia-Pacific Journal of Physics

International Journal of Fluid Mechanics & Thermal Sciences

SCI Chemistry with included AKS assessment

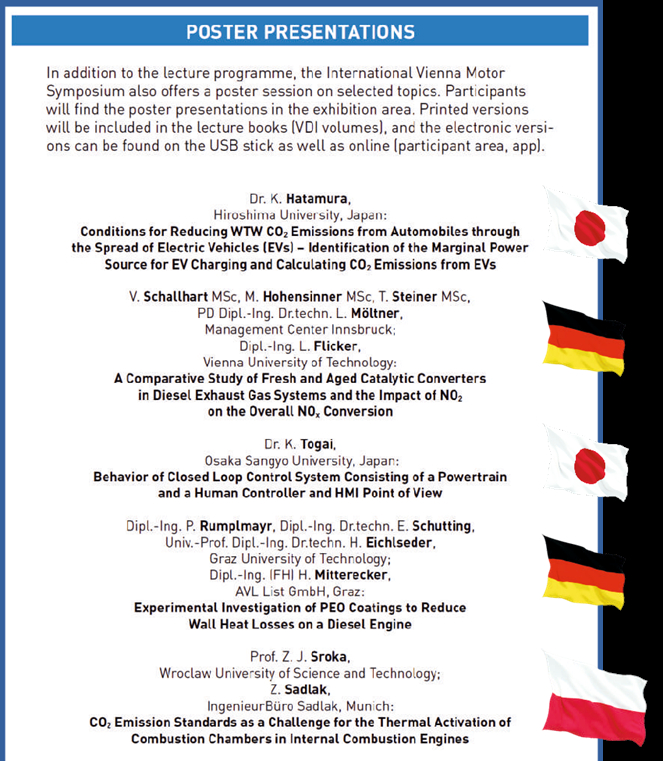

Scientific article about AKS prepared by scientific consultant Prof. Zbigniew Sroka, PhD, Eng., the head of the Vehicle Engineering Department at the Wrocław University of Science and Technology, has been recognized by international teams of scientists.

CONGRATULATIONS!

We have read your valuable article titled Thermal activation of the combustion chamber of a reciprocating engine, which appeared in the Journal of Thermal Science, and its topic has made a great impression on us. It has attracted the attention and interest of researchers and scholars specializing in this field." - SCI Chemistry.

Vienna Motor Symposium

As one of five presentations in the corridors of technical universities from all around the world, and the only one in the entire symposium program with an engine efficiency improvement of over 60%. (No changes made)

Do you want to be a part of AKS's success and buy shares?

Email us at: office@aksactive.com lub tel. 794 608 875

(some informations might be not updated)